Comprehensive introduction

JX-300XP control system is one of SUPCON WebField series control systems of Zhejiang zhongkong Technology Co., Ltd. The application scope of the system has covered chemical industry, oil refining, petrochemical, metallurgy, electric power and other industrial automation industries. JX-300XP control system simplifies the system structure of industrial automation, enhances the function and efficiency of process control, improves the integrity and stability of industrial automation, and finally saves the investment made by enterprises for industrial automation, truly reflects the open spirit of industrial basic automation, makes the automation system realize networking, intelligence and digitization, and breaks through the concepts and functions of traditional DCS, PLC and other control systems, It also realizes the reasonable unification of process control and equipment management in the enterprise.

Functional highlights

• Openness

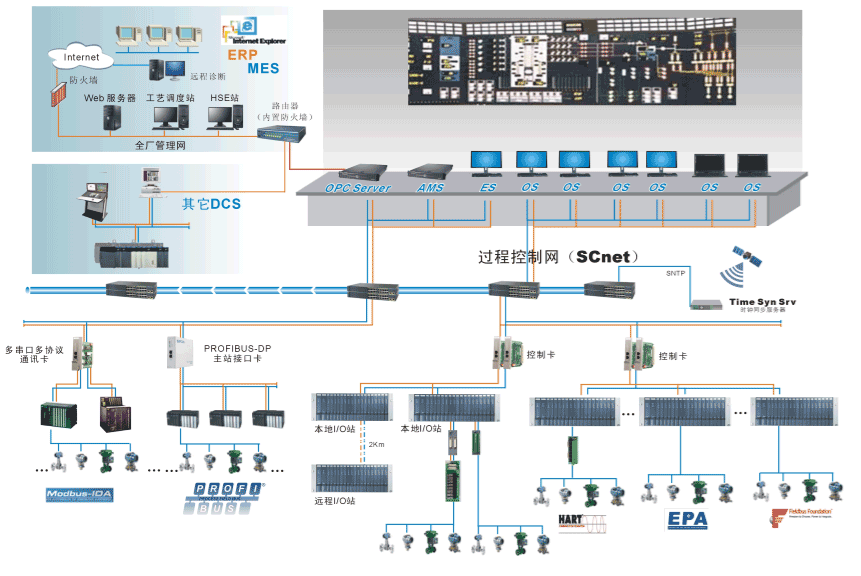

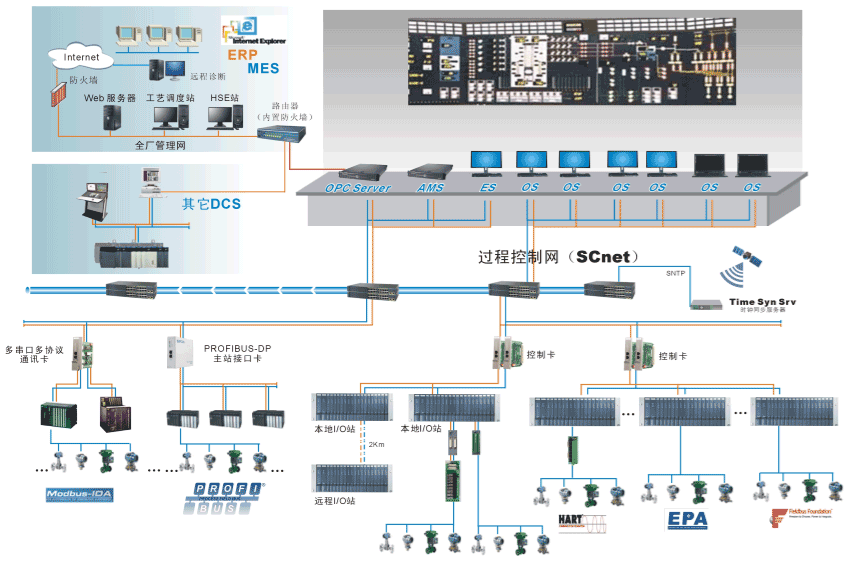

• integrating various standardized software and hardware interfaces, users can interact with DCS through OPC data interaction protocol, tcp/ip network protocol and other open interfaces at different levels. Through the Internet Interconnection of modbus, PROFIBUS-DP, Hart, hostlink and other protocols, it is convenient to access advanced fieldbus equipment, third-party distributed control systems, logic controllers, etc.

• Possibility

• the anti-corrosion capacity of the system complies with the environmental pollution level G3 standard defined by ansi/isa s71.04; The electromagnetic compatibility (EMC) level of the system meets the industrial level II standard.

• Equipment management

• Add advanced equipment management function (AMS), which can automatically manage the parameters setting of the intelligent transmitter of the fieldbus, and achieve the perfect combination of equipment management and process control.

• Any redundant configuration

• The power supply, main control card, data transfer card, analog quantity card and some switch quantity cards of JX-300XP control station can be configured according to the requirements of non redundancy or redundancy. The power supply, communication bus, main control card, communication interface card and i/o card of the system all support 1:1 thermal redundancy. Once the working module fails, it can automatically switch to the standby module without interference

• Powerful online download function

• Fault diagnosis

• It has the fault diagnosis function of cards, channels, transmitters or sensors, with a high degree of intelligence, and can easily eliminate the faults such as thermocouple disconnection.

• Network structure diagram

Technical specifications

Communication capability:

JX-300XP system adopts mature computer network communication technology to form a high-speed redundant data transmission network to realize the timely transmission of process control real-time data and historical data. At the same time, it realizes the comprehensive integration of a variety of bus compatibility and heterogeneous systems. Various domestic and foreign DCS, PLC and field intelligent devices can be connected to the JX-300XP control system, making it an open distributed control system with full digitalization, flexible structure and perfect functions.

Technical specifications:

The maximum system configuration supports 63 control nodes and 72 operation nodes, with a data scale of 20000 points.

Functional highlights

Openness

Integrating various standardized software and hardware interfaces, users can interact with DCS through OPC data interaction protocol, tcp/ip network protocol and other open interfaces at different levels. Through the Internet Interconnection of modbus, PROFIBUS-DP, Hart, hostlink and other protocols, it is convenient to access advanced fieldbus equipment, third-party distributed control systems, logic controllers, etc.

Possibility

The anti-corrosion capacity of the system meets the G3 standard of environmental pollution level defined by ansi/isa s71.04; The electromagnetic compatibility (EMC) level of the system meets the industrial level II standard.

Device management

The advanced equipment management function (AMS) is added, which can automatically manage the parameters setting of the intelligent transmitter of the fieldbus, and achieve the perfect combination of equipment management and process control.

Any redundant configuration

The power supply, main control card, data transfer card, analog quantity card and some switch quantity cards of JX-300XP control station can be configured according to the requirements of non redundancy or redundancy. The power supply, communication bus, main control card, communication interface card and i/o card of the system all support 1:1 thermal redundancy. Once the working module fails, it can automatically switch to the standby module without interference

Powerful online download function

Fault diagnosis

With the fault diagnosis function of cards, channels, transmitters or sensors, it has a high degree of intelligence and can easily eliminate the faults such as thermocouple disconnection.

Network structure diagram

Technical specifications

Communication capability:

JX-300XP system adopts mature computer network communication technology to form a high-speed redundant data transmission network to realize the timely transmission of process control real-time data and historical data. At the same time, it realizes the comprehensive integration of a variety of bus compatibility and heterogeneous systems. Various domestic and foreign DCS, PLC and field intelligent devices can be connected to the JX-300XP control system, making it an open distributed control system with full digitalization, flexible structure and perfect functions.

Technical specifications:

The maximum system configuration supports 63 control nodes and 72 operation nodes, with a data scale of 20000 points.